Service Platforms

Service platforms can be manufactured using a number of different materials according to the customer’s wishes. Our service platforms can be delivered as turnkey solutions or in smaller partial deliveries, scaling from just a few square metres to several hundred square metres. We design service platform structures in a 3D environment, where parametric design models are used to optimise cooperation between design and manufacturing.

- Layout drawings

- Customer’s drawings

- Dimensions taken by Premekon’s designer

We offer a range of off-the-shelf service platform solutions that can be adapted to the location as well as the customer’s standards, special requirements and chosen materials.

Production Line Machinery Service Platforms

arrow_right_altService platforms for production line machinery can also be mounted on rotating platforms.

We can make even the most complex structures for customers’ equipment and machinery.

Rotating base

The stresses caused by the moving and vibrating machinery are taken into account in the installation and structure of the railings

OUR PRODUCTION LINE MACHINERY SERVICE PLATFORMS ARE ALWAYS BUILT TO STANDARDS AND REQUIREMENTS

Every year, Premekon delivers several service platform systems that cover entire production lines. These production lines mostly belong to the forest and sawmill industries, and the service platform systems are equipped for the special requirements of the application, such as:

- Safety guards and mesh barriers

- Rotating and detachable service platforms and railings

- Mobile rolling service platforms and stairs

Contact person

Stainless-Steel Platforms

arrow_right_altSteel service platform structures are manufactured in their own production cell with automated component manufacturing stages using a laser tube and sheet cutting machine, drill line and plasma cutter. The frames of Premekon’s service platforms are made out of angle iron or by bending metal plates into shape, and the walking surface can consist of grating, checker plate or, for example, perforated plate.

Service platform elements are welded together before delivery and installed with bolts. Assembling service platform systems with bolts ensures a good fit and reduces welding at the installation site.

Contact person

Aluminium Platforms

arrow_right_altAluminium service platforms use a special walking surface profile, providing excellent slip resistance regardless of direction of travel. Railings are mounted using separate connectors made from aluminium profiles, which allow the railing to be removed easily and do not leave any visible connecting elements.

Aluminium railing mounted with detachable flange

Premekon product: toe board profile for aluminium platform

Premekon’s aluminium service platforms are made on a dedicated production line equipped with fully automated component manufacturing stages. Aluminium service platforms are made by welding, after which they are anodized. Anodizing improves the structure’s corrosion resistance, allowing it to be used in even the most challenging of environments. Aluminium service platforms weigh roughly 50% less than an equivalent steel service platform.

Contact person

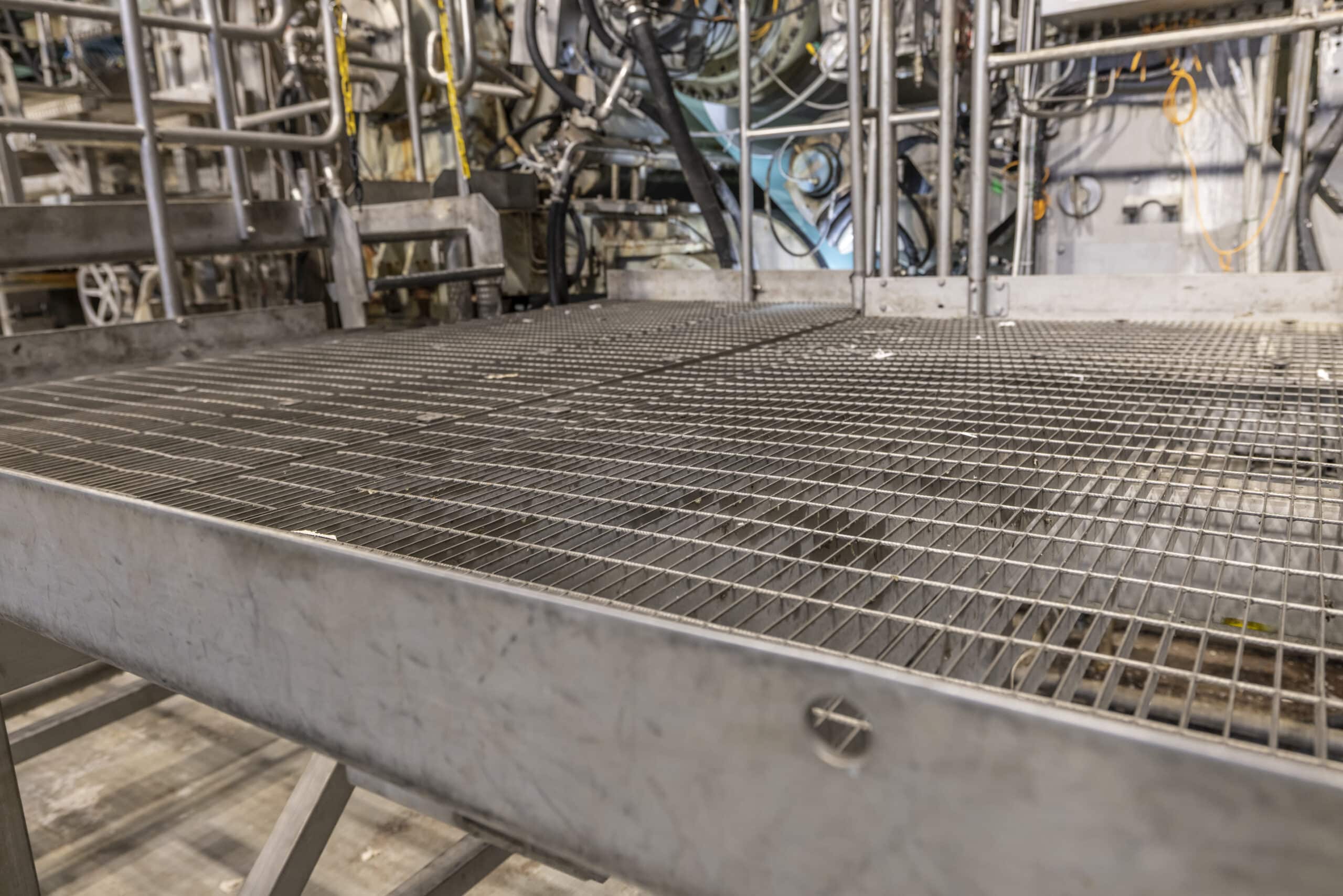

Grating Platforms

arrow_right_altGrating platforms allow for personnel to walk from one place to another or access areas for purposes such as maintenance or inspections. Grating platforms are a standard component of large equipment, machinery and buildings because they make working in and around them significantly easier.

We design and install grating platforms according to your needs.

Lifting points make installation faster and ease maintenance tasks.

AVAILABLE IN THE FOLLOWING MATERIALS

- Structural steel (painted or hot-dip galvanized)

- Stainless steel

- Acid-proof steel

Stainless steel is particularly corrosion resistant in challenging environments. Each delivery is a project all its own, during which we will help you choose the best possible structure solution for your needs.

When installing grating platforms, we choose the ideal grating type according to your needs. Grating profiles offer different surface roughness, mesh size and height, which allows us to pick the ideal grating profile for the application, also affecting the safety of the platform.

WE OFFER GRATING PLATFORMS AS TRUNKEY DELIVERIES FROM DESIGN THROUGH INSTALLATION

We ensure our products meet all necessary standards and are well suited for your needs through painstaking design, 3D modelling and high-quality manufacturing processes. Our extensive experience of working in project environments ensures that our products meet all standards and requirements. Premekon’s grating platforms conform to the EN 14122 service platform standard or the standards of the destination country, as well as the standards of the particular customer or plant.

Our grating platforms are primarily intended for use in and around industrial machinery and buildings. We deliver to industrial companies of all sizes.

Turnkey delivery is the easiest way to get exactly the grating platforms you need. When you let us take care of designing, manufacturing, delivering and installing you grating platforms, you save time resources that you can then redirect to your core business.

Find out more about our project flow in our article Premekon Grating Platforms Delivered to the Forest Industry.

Contact person

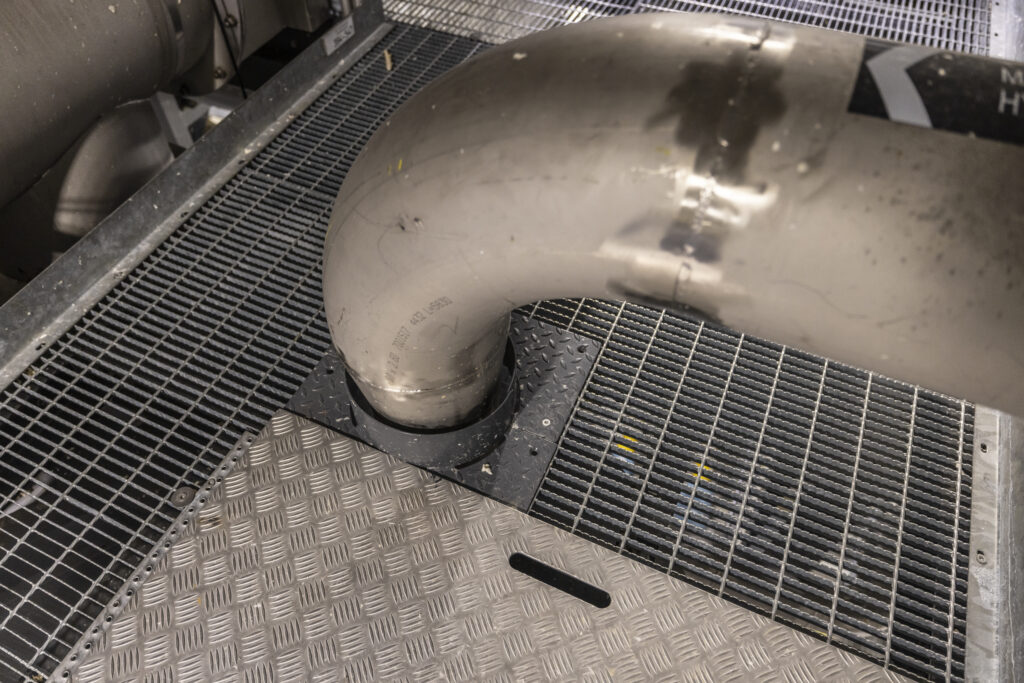

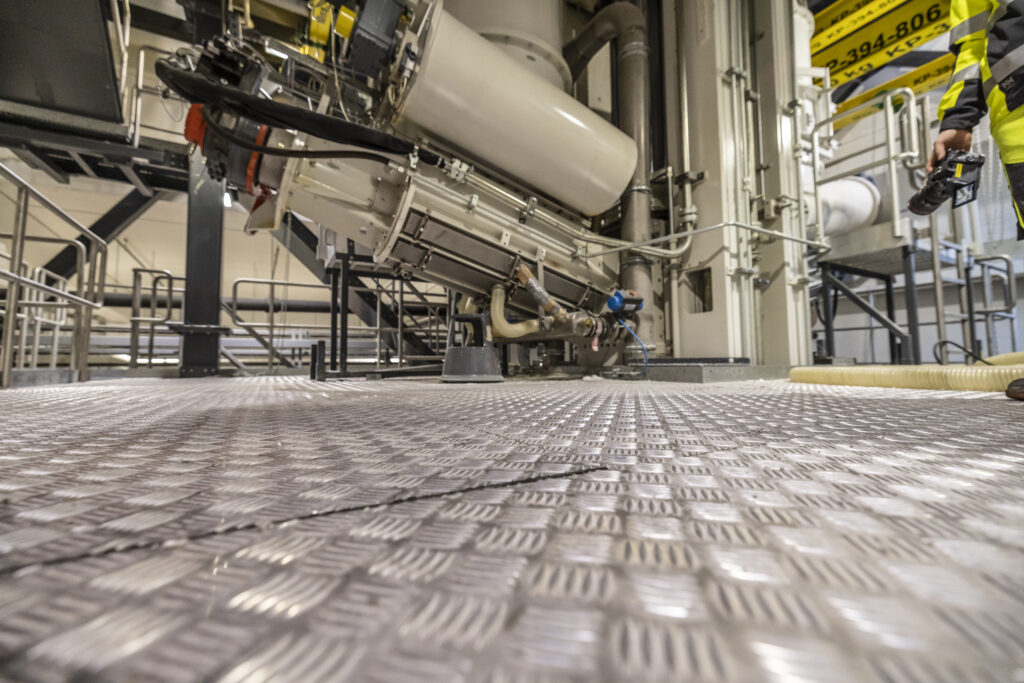

Checker Plate Platforms

arrow_right_altChecker plate platforms allow for safe access routes to places such as maintenance and inspection points. Checker plate platforms are ideal for places where you want to prevent dirt and loose items from falling through the platform. The raised pattern improves grip significantly when walking.

The closed surface (in comparison to grating platforms) also makes moving and working at heights easer when there is no need to have direct line of sight through the platform.

Checker plate platforms allow for safe access routes to places such as maintenance and inspection points. Checker plate platforms are ideal for places where you want to prevent dirt and loose items from falling through the platform. The raised pattern improves grip significantly when walking.

The closed surface (in comparison to grating platforms) also makes moving and working at heights easer when there is no need to have direct line of sight through the platform.

The raised pattern provides improved grip when walking.

The closed surface prevents dirt from falling through.

AVAILABLE IN THE FOLLOWING MATERIALS

- Structural steel (painted or hot-dip galvanized)

- Aluminium

- Stainless steel

- Acid-proof steel

WE DELIVER CHECKER PLATE PLATFORMS TO COMPANIES OF ALL SIZES

We deliver checker plate platforms as turnkey deliveries from design through installation. We take responsibility for ensuring the solution meets all requirements. Premekon’s checker plate platforms are in line with the EN 14122 platform standard.

Premekon most commonly serves international industrial firms, but we deliver products to companies of all sizes. Our many years of experience ensure we know every requirement and standard that applies to checker plate platforms. When you order platforms from Premekon, you are also saving time in your own projects.

Read our article: Delivering Checker Plate Platforms to Nordkalk

Contact person

Catwalks

arrow_right_altAVAILABLE IN THE FOLLOWING MATERIALS

- Structural steel (painted or hot-dip galvanized)

- Stainless steel

- Acid-proof steel

Catwalks are a solution for places where personnel need an access route over something like a paper mill conveyor line with minimal support structures. In this scenario, the production line below also needs to be protected from dirt falling from above.

Our catwalks are built with closed and durable checker plate surfaces. Where necessary, catwalks can also be equipped with heating pipes and a double floor.

Catwalk delivery to a forest industry customer – Explore an example of our turnkey delivery

WE TAILOR CATWALKS TO THE CUSTOMER’S REQUIREMENTS

We design catwalks for industrial applications and production lines. We work smoothly with business customers of all sizes. We are a reliable partner for both SMEs and large projects.

Our catwalks conform to the EN 14122 service platform standard or the standards of the destination country, as well as the standards of the particular customer or plant.

At Premekon, we have extensive experience in service platform projects and the associated standards and requirements. As our customer, you can leave all the project work to us without having to worry. We will take care of the whole process from design to installation. With responsibility for the product’s requirements and suitability for purpose with us, you can safely focus on your own projects.

Contact person

Lataa esitteemme