Design Solutions

By combining design and manufacturing under one roof, we are able to offer our customers a number of benefits. Thanks to this, our operations are highly flexible and efficient, ensuring that the steel structures our customers need are completed quickly and to a high standard of quality.

Turnkey Solutions

From the customer’s perspective, Premekon’s turnkey approach is the best and easiest solution. Our turnkey approach consists of design and manufacturing, as well as assembly and installation if needed.

The cost-effectiveness of our turnkey approach comes from rapid information flows between design and manufacturing personnel, which allow us to quickly deliver the high-quality steel structures our customers need. Our turnkey approach also offers customers a flexible solution that is able to react to changes quickly, because each part of the process takes place at the same location.

Premekon’s goal is to serve customers in a comprehensive way, and services are a key element of Premekon’s business. When it comes to service platform and steel structure deliveries, Premekon provides design, assembly and installation services, allowing our customers to get everything they need in one place.

Design

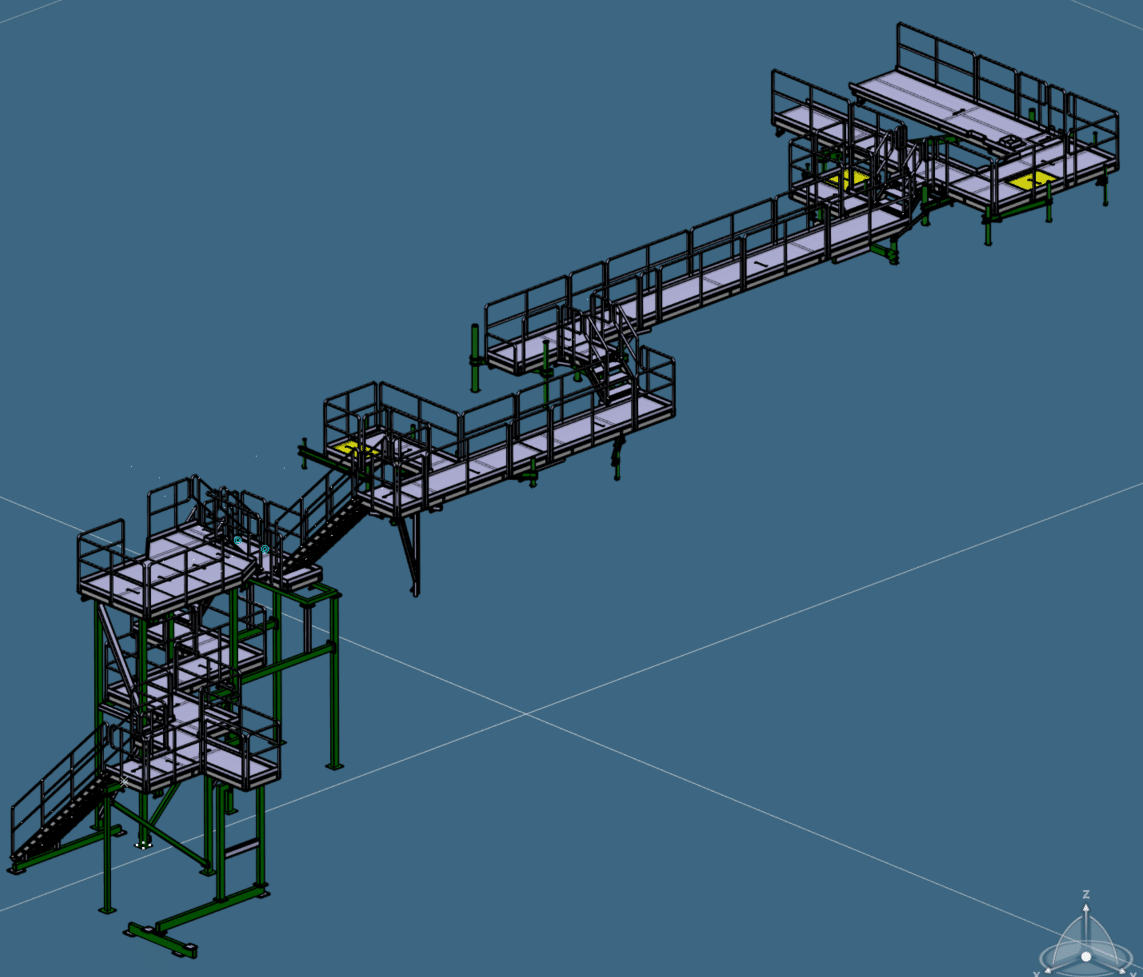

Our design process usually begins with the customer’s layout drawings, but Premekon’s designers can also measure the customer’s premises if these drawings are not available. To create our designs, we use the newest 3D applications, utilising Catia V5 software and two Solidworks workstations. We also employ more-traditional CAD software.

Our parametric 3D designs and technical drawings are compliant with the EN 14122 (1–4) and OSHA standards. We also consider any plant-specific standards in the design process. 3D design allows for accurate clash analysis in the design phase, avoiding the need to make changes to structures in the installation phase. Our designs include the necessary strength calculations, and we also provide comprehensive strength calculation reports when necessary.

There are a number of benefits to having design and manufacturing under the same roof. It allows for flexibility and makes it possible to react quickly to changes thanks to seamless communication between the design and manufacturing teams. Premekon’s different units work together throughout a project, with design supporting both manufacturing and installation efforts.

Installation

Premekon offers preassembly of equipment and machinery, allowing products to be tested and inspected before transport to their final location. Some products can be delivered in an assembled state.

Assembly of equipment and machinery is also available as a separate service. Premekon’s large facilities and lifting equipment allow us to manage even large assemblies.

Where necessary, Premekon can take over responsibility for installing products at their final location, with our experienced installation team providing a turnkey delivery. The installation service is available for Premekon deliveries to any location. When it comes to large projects, customers can opt for installation supervision or management services instead of the full installation service.

Safety

Safety Surveys

Premekon Service Platform Safety Survey

Virtually every older facility has issues when it comes to the safety of equipment and machinery. Safety surveys in line with the Machinery Directive and Safety of Machinery standard are an easy way of assessing the safety of a factory or plant’s access platforms, guard rails and machines.

Premekon’s professionals usually complete a survey in one or two days. The customer then receives a comprehensive and detailed report of any issues, complete with proposed solutions. If necessary, Premekon can deliver turnkey repairs to any detected shortcomings in a way and scope agreed upon with the customer.

Standards referenced:

Machinery Directive 2006/42/EC

ISO 14122 Safety of Machinery

To find out more, please contact: